Parkwest Surgery Bed Tower Additions & Renovations

Parkwest Medical Center

Project Name

Parkwest Surgery Bed Tower Additions & Renovations

Parkwest Medical Center

Service

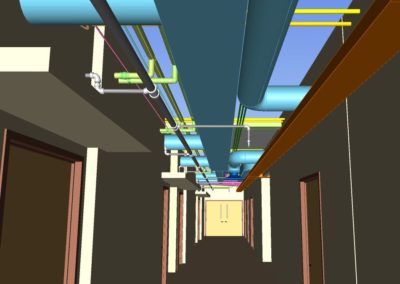

3D BIM Coordination – Mechanical, Piping & Plumbing Systems

Completion Date

2019

Size

150,000 sq. ft.

Project Budget

$99,000,000

The Problem

This project was an addition and a renovation of an existing, in operation hospital. Space constraints in the existing portion of the facility were design and construction challenges.

- Overflow Drain Pipe

- BIM conflict identification revealed a 175 feet run of overflow drain pipe was running through Operating Room ductwork on its way to daylight. Additionally, the slope requirements of the pipe placed the piping below the ceiling height of the programmed space by the time it reached the building exterior.

- The problem encompassed approximately 4,000 square feet of space and affected every trade within the layout.

- Chilled Water and Steam Piping

- BIM conflict identification revealed the Second-Floor chilled water mains and steam piping unable to follow the designed layout.

- Intended routing over mechanical rooms produced conflicts with system distribution infrastructure and routing above exterior patient rooms produced conflicts with structure.

Actions Taken

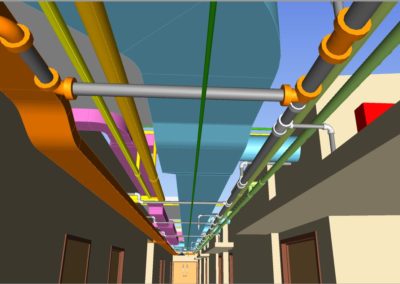

- Paladin identified and presented the major clashes through bi-weekly BIM Coordination meetings.

- We worked with the BIM Coordination team to resolve issues we could and present various alternate solutions for the remaining issues.

- Any design modifications involved the Design Team and the Hospital Administration

- Overflow Drain Pipe – It was determined that the slope of the overflow drainpipe could not change. Consequently, the design team reworked structure, ceiling, mechanical, electrical, and plumbing system conflicts in order to accommodate the overflow drain.

- Steam Piping – Due to slope requirements, the steam pipe remained in the originally proposed routing.

- Chilled Water Pipe – Ultimately, space limitations prohibited the internal routing of the chilled water piping to its intended destination. As a solution, the pipe was rerouted through the first floor penetrating a low roof to enter the second-floor mechanical room.

- The design team issued changes which Paladin incorporated through 3D Autocad into the BIM Model.

Results

- Found issues in BIM before system installation

- Contractor savings

- Overflow Drain Pipe – an estimated $124,000 in labor and materials cost in reworking after installation.

- Chilled Water and Steam Piping – an estimated $27,000 in labor and materials in reworking after installing

- Saved the Owner in Change Order costs

- Achieved Sign-Off of the area in time for production.